典创承诺:五年质保(人为损坏及自然灾害除外)对产品终身维护.

礼堂椅4系列

材质说明

背绵:采用冷发泡定型绵,密度高达55公斤/米3。

座绵:采用海绵+钢架+橡皮筋一体发泡成型(加厚),密度高达60公斤/米3。

座、背外壳:采用优质多层板热压成型,并面压实木皮。

布料:采用优质麻绒。(BJ-9228椅座、椅背拉线定位并加垫丝光绵)

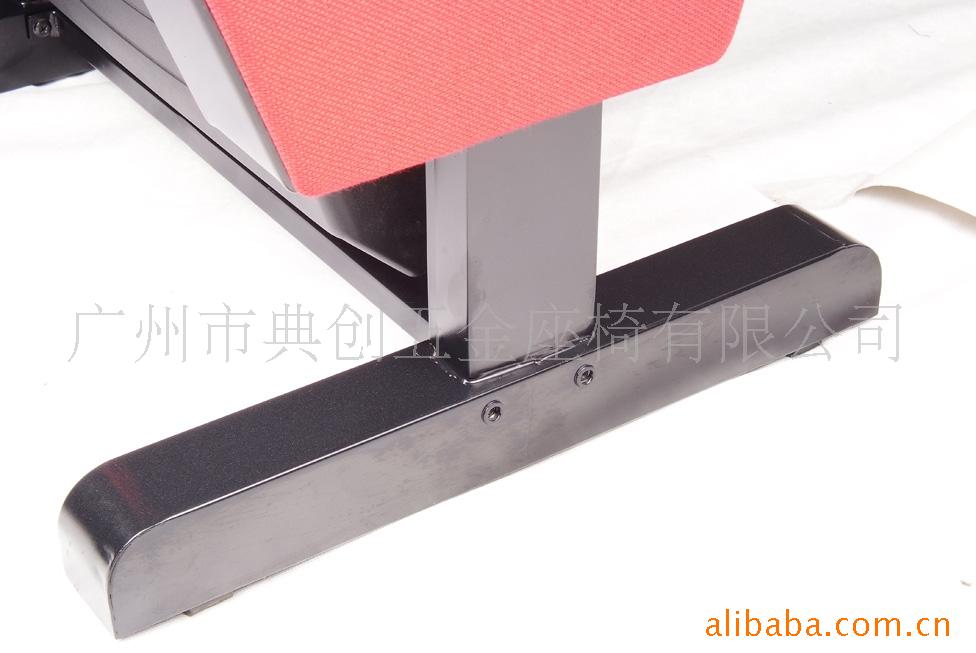

扶手框架及站脚:采用3mm厚优质钢板冲压焊接成型,经打磨、除锈、防氧化、静电喷粉、高温锔炉等工序处理。

扶手盖:采用进口原木加工成形。

侧板:采用ABS压注成型,面覆海绵和麻绒,并采用活动式扣钉,易于拆装。

回复机构:采用重力回复机构,不存在故障,持久耐用。

地爆螺丝:采用不锈钢内六角膨胀螺丝。

特别说明:扶手框长度为470mm,更符合人体工程学,并使及扶手盖打开无障碍。

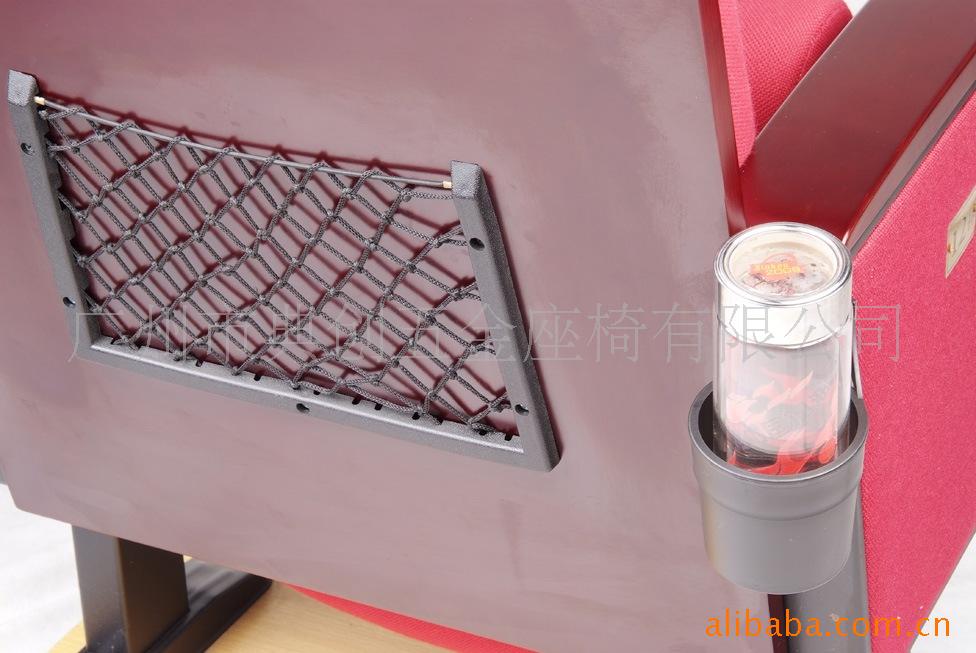

可选配件说明

1)写字板:采用高密度板,面压防火板;连接横条为铝合金压注成型。

2)加强型连接结构:在背包下面装有加强横管,椅座的受力点作用在横管上,较之传统座椅的受力点在椅背底部的海绵上更为耐用、牢固

3)布料:可根据客户要求进行3M(防潮、防尘、防污)处理。

4)前置、后置杯架:采用PP压注成型。

5)号码、行码牌:采用夜光或铝合金材质。

Auditorium seating 4 series

Specifications

Back Cotton: cold foaming shaping sponge with a density as high as 55 kg / m 3.

Block Sponge: The sponge + steel + rubber band foam molding body (thicker), density of up to 60 kg / m 3.

Seat, back shell: high quality multilayer compression molding, and surface compaction veneer.

Fabric: high quality hemp. (BJ-9228 the seat, pull back and padded mercerized cotton positioning)

Handrail frame and stand feet: A good quality 3mm thick steel plate stamping, welding and forming, after polishing, rust, oxidation, electrostatic powder coating, high temperature processes to deal with curium furnace.

Armrest cover: The processing of imported logs forming.

Side: pressure injection molding with ABS, side cover sponge and hemp, and the use of movable fasteners, easy disassembly.

Reply institutions: The institutions of gravity back, no fault, durable.

To burst screws: Hexagon expansion of stainless steel screws.

Special Note: handrail frame length 470mm, more ergonomic and to open the barrier and handrail cover.

Optional description

1) Frame: high density board, fire board surface pressure; connection bar of aluminum alloy pressure injection molding.

2) enhanced connecting structure: In the backpack containing the following to strengthen horizontal tube, the seat of the role of stress points in the horizontal pipe, than the traditional seat of the point in the back of the bottom of the sponge is more durable, solid

3) Fabric: according to customer requirements 3M (moisture, dust, pollution) treatment.

4) pre-and post cupholders: The PP pressure injection molding.

5) number, line number and card: using luminous or aluminum.

选配件特写: